Overview

The idea is simple: fabricate a beam

connected to two anchors. When a voltage is applied to the beam,

the flow of current causes it to heat up, expand, and deflect:

The center of the beam is

offset slightly to control the direction of deflection. The beam

deflects far more than it would if it were simply cantilevered

from a single anchor. The amplification factor can be calculated

by using concepts from solid mechanics.

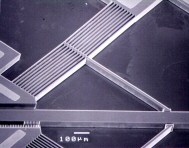

We designed and fabricated

high-aspect-ratio thermal actuators from single-crystal silicon

using deep reactive ion etching (DRIE). These images show the actuators at work:

(Animation created by

using thermomechanical models in ANSYS 5.5; videos

recorded from a CCD camera mounted on a

probe station.) We go from the operational concept to a single 1 mm beam to arrays of beams, then to linear motors containing sliders nudged along by arrays.

The actuators are fabricated

from silicon-on-insulator (SOI) wafers using metallization,

DRIE, and HF etching. The HF etch is timed to release the beams

without completely undercutting the large anchors. Gold pads on

the anchors provide electrical connectivity. Vernier gauges are

attached to the actuators to permit deflections to be measured.

High-aspect-ratio actuators

fabricated with DRIE can generate significantly higher forces

than surface micromachined polysilicon thermal actuators.

Additionally, problems such as stiction and out-of-plane bowing

are avoided. We have demonstrated deflections exceeding 25

µm and forces exceeding 2.5 mN for a current input of 20 mA.

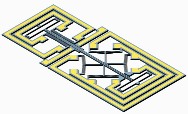

We have focused on V-beam

actuators for motor applications because these actuators produce

translational motion only, as opposed to the coupled

translational and rotational motion produced by U-beam actuators.

When fabricated in parallel arrays and connected by a center

yoke, as shown in the video above, the resultant force scales up

with the number of actuators.

In the linear motor,

actuators are arranged in clamping and positioning arrays. The

motor works by advancing a slider through frictional contact. By

alternately positioning and clamping the slider, a very large

range of motion is available. The clamping ability allows the

motor to interact with compliant mechanisms and maintain a

specified position. This capability makes this type of motor

an excellent choice for integration with 3DMEMS

devices.

The efficiency of these thermal

motors is extremely low, approximately 0.0000001. This low

efficiency limits the use of microactuators in low-power

applications such as self-sufficient robotics. However, the

actuators are useful in stationary applications. For example, the nanotechnology company Zyvex uses thermal actuators in a nanomanipulation system.

Modeling

A key part of this work is the

estimate of the time constant of these thermal actuators.

Because the length of a typical

actuator beam is considerable larger than height or width, a 1-D

differential element is used to model the temperature

distribution in the silicon. This element, with height h,

width w, and thickness dx, is illustrated below,

where the current flux J represents the current per unit

area through the element.

In

this diagram, the current flux J represents the current

per unit area through the element. The material properties shown

are the resistivity ρ, the silicon thermal

conductivity ks, and the air thermal

conductivity ka.

It has been shown that, in the

case of a very small gap under a suspended beam, the effects of

convection and radiation are negligible and conduction through

air to the substrate dominates. However, conduction from the

sides of the beam through the surrounding air to the substrate is

not negligible and must be accounted for by the shape conduction

factor S. This parameter is typically found via finite

element analysis.

Because of the relatively large

thickness of the substrate (525 µm),

the large 600 µm × 600 µm

anchors, and the high thermal conductivity of single-crystal silicon, the substrate

and anchor temperatures are assumed to remain at ambient

temperature. Finite element analysis of the complete geometry has

shown this assumption to be reasonable. The thermal conductivity

of air and the resistivity of silicon are assumed to be

independent of temperature. Also, the thermal conductivity and

thermal expansion coefficient of silicon are initially assumed to

be independent of temperature to make the heat equation

tractable.

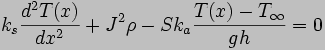

By using the differential

element above and dividing by the element volume, the

time-independent heat equation can be written as

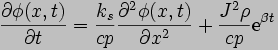

The transient response of the

V-beam thermal actuators can be predicted by examining the

time-dependent form of this equation:

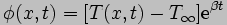

where the values of the specific

heat c and density p of silicon are assumed to be independent of

temperature, and the following variable substitutions have been

made:

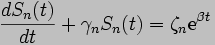

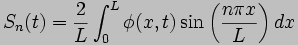

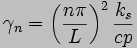

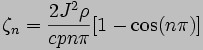

Applying the finite Fourier

transform to the time-dependent equation results in the following

nonhomogeneous differential equation:

where

This equation has the solution

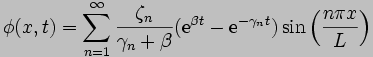

to which the inverse finite

Fourier transform can be applied:

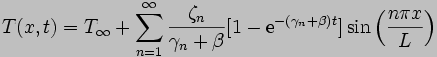

The general solution is

therefore

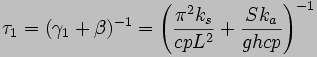

implying a first-mode time

constant of

which offers a useful way of

comparing heat loss contributions from beam conduction and air

conduction. The first term represents heat loss through the beam

to the anchors; the second term represents heat loss through the

air gap to the substrate. By using typical values, a typical

V-beam actuator with a length L of 1000 µm,

a width w of 10 µm,

and a height h of 50 µm

is predicted to have a first-mode time constant τ1

of approximately 0.8 ms. The corresponding cut-off frequency is

approximately 200 Hz.

Transient experiments were

performed on the V-beam actuators with a laser Doppler

vibrometer. These tests were performed by mounting a chip

vertically and focusing the laser on the side of an actuator

beam. The normalized frequency response is shown below. As

expected, the full range of motion is maintained at low

frequencies. As the frequency increases past 100 Hz, response

drops 20 dB per decade because the actuator cannot complete each

heating/cooling cycle fast enough to keep up with the signal. By

fitting a curve to the frequency response, the time constant of

this actuator is estimated at 1.6 ms, as shown as the solid line

below.

It would seem that the transient

model is off by a factor of two. In fact, the earlier calculation

was performed with the room temperature values of silicon thermal

conductivity and specific heat. However, we know from resistance measurements and from visual observation of glowing silicon that portions of the actuators exceed 500°C during operation. What happens if high-temperature

values are used? If we take the material properties at

around 500°C, the calculated time constant is 1.8 ms. So the

experimental results are actually bounded by estimates using

temperatures of 25°C and 500°C. For better accuracy, we would need to model the beam by multiple elements, each with its own temperature and material properties.

Impact

This work was published here in 2004. Since then, our modeling and fabrication

work has been cited by over 100 papers investigating

electrothermal actuation and its applications and by the

books Modeling MEMS and NEMS by Pelesko and Bernstein (CRC

Press, 2002), RF MEMS: Theory, Design, and Technology by Rebeiz (Wiley 2003), Micromanufacturing and Nanotechnology by Mahalik (Springer, 2005) and MEMS Linear and Nonlinear Statics and Dynamics by Younis (Springer, 2011).

|