|

From 1999 to 2001 I worked on the DARPA-funded 3DMEMS

program at the University of

Maryland. My advisor was Prof. Don DeVoe.

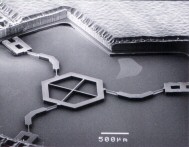

Pictured at left is a 3-DOF parallel manipulator originally

designed by Prof.

Lung-Wen Tsai and prototyped by Rick Stamper

at the University

of Maryland. The 3DMEMS effort began as a collaboration between

Prof. DeVoe's MEMS group and Prof. Tsai's mechanisms group.

As envisioned by DeVoe and Tsai, the primary goal

of the 3DMEMS program is to develop, demonstrate, and apply a batch

fabrication process to construct 3-D microsystems. The process takes

advantage of recent developments in silicon-based fabrication technology

such as fusion bonding and deep reactive ion etching (DRIE). This

research is expected to enable batch fabrication of mechanically robust

micromechanisms that are capable of true 3-D motion

The essential ideas of the 3DMEMS process are:

-

Robust, true 3-D capability: A true 3-D fabrication

process must be capable of producing devices with characteristics

such as overhangs, out-of-plane joints, and enclosed cavities.

The traditional criticism of MEMS is that devices are simply

extrusions of 2-D patterns.

This is certainly the case when bulk micromachining processes

such as DRIE are used without any modifications. While multi-layer

processes such as MUMPsŪ*

and SUMMiT

can be used to produce true 3-D devices, the thin structural layers

associated with surface micromachining are extremely compliant. The

3DMEMS process combines the mechanical strength of

high-aspect-ratio devices with the true 3-D capability of

multi-level processes.

*Note: this overview

was written in 2001. A MUMPs process (SOIMUMPs) now exists wherein

users can create high-aspect-ratio structures.

-

Silicon-on-insulator

(SOI) wafers: Single crystal silicon (SCS) was chosen as

the 3DMEMS structural material because of its favorable

mechanical and electrical properties.  For example, SCS has no

grain boundaries, making it a perfectly elastic material.

Additionally, silicon possesses a stable, insulating

oxide. SOI wafers feature a thin silicon layer separated from a

thick silicon substrate by an oxide layer. Because the 3DMEMS process uses two SOI wafers, only

one aligned bonding step is required to produce several

structural layers. For example, SCS has no

grain boundaries, making it a perfectly elastic material.

Additionally, silicon possesses a stable, insulating

oxide. SOI wafers feature a thin silicon layer separated from a

thick silicon substrate by an oxide layer. Because the 3DMEMS process uses two SOI wafers, only

one aligned bonding step is required to produce several

structural layers.

-

Batch fabrication:

Once masks are produced for photolithography, subsequent process

steps fabricate all the devices on the wafer simultaneously.

Although many 3-D microfabrication processes have been explored

by other groups, most require individual or sequential device

fabrication, which increases manufacturing time and expense. The

use of batch fabrication permits the simultaneous fabrication of

hundreds or thousands of devices.

-

Parallel manipulation: In general, manipulators can be

fabricated in either serial or parallel configurations. A

parallel manipulator allows multiple degrees of freedom to be

attained while all of the actuators remain on the base. In

contrast, a multiple-DOF serial manipulator requires some form

of actuation at the intermediate joints. Since it is not practical

in our case to

mount microactuators on moving links, all control

inputs to the micromanipulator must originate from the fixed base.

-

Linear actuation: Tsai's 3-DOF parallel

manipulator employs rotational electromagnetic actuators to position the platform. At the

micro-scale, however, it is easier to design and fabricate a linear

actuator. Our design uses linear 1-DOF slider inputs. We chose

electrothermal motors as an actuation method because they can produce

relatively high forces and are relatively simple to fabricate. In

fact, our electrothermal linear motor design

is very compatible with the 3DMEMS fabrication process, requiring only

the addition of a metallization step to create bond pads.

-

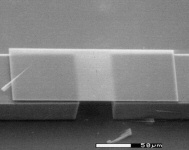

Compliant joints: The macro-scale version

uses hinges to achieve in-plane and out-of-plane

motion. Our design replaces these hinges with compliant, or

flexural, beams. A close-up view of an out-of-plane joint is shown

at right. Compliant beams can be used to mimic the

behavior of hinges without the associated "slop" resulting

from clearances between hinge components. Part of the 3DMEMS

research program involves modeling the

behavior of compliant joints.

A large portion of my graduate work involved

developing

and refining the 3DMEMS process. Around April 2001, when I

graduated, we wrapped up the first fabrication run, completing the

first out-of-plane joints. This joint was constructed by bonding together

the patterned active layers of two SOI wafers. The actual joint, which

is only 2 microns thick, is part of the active layer of the top SOI

wafer. The substrate of that wafer is used to form caps that hold

the sliders in place.

Shown below are conceptual views of a

three-degree-of-freedom (3-DOF) spatial platform micromanipulator

(images rendered in AutoCAD 2000 from the original design files). This

device was designed by Zhongzhou Tang and me. A spatial manipulator is

just one example of a device that can be fabricated using the 3DMEMS

process. Envisioned applications for similar devices include sample

positioners for scanning electron microscopes, tools for

minimally-invasive surgery, and dexterous linkages for

microrobots.

All 3-D microfabrication was

conducted with the help of my colleagues Dave Schreiber and Brett

Piekarski of the Maryland MEMS Lab.

Some fabrication was performed at the Army

Research Laboratory. The

assistance of Tom Loughran and Nolan Ballew is gratefully

acknowledged.

|