Back to table of contents | Next section

1.1 Overview

There are two objectives of the research described in this thesis. The first objective is to develop a process for fabricating three-dimensional micro electro mechanical systems (3DMEMS) in single crystal silicon (SCS). The features of this batch fabrication process are to include high yields, minimum complexity, and the capability of producing true 3-D devices with characteristics such as overhangs, out-of-plane joints, and enclosed cavities. The second objective is to investigate a method for positioning these devices by means of electrothermal actuation.

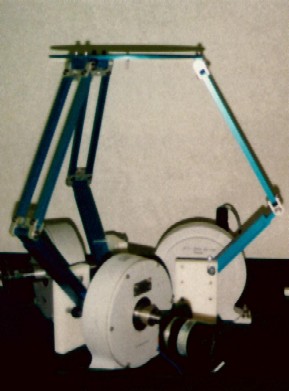

This research was performed as a part of the 3DMEMS program at the University of Maryland at College Park. The ultimate goal of this program is to develop processing and design technology for the fabrication of 3-D microstructures that are capable of coupling macro-scale forces to micro-scale displacements. Envisioned applications for these microstructures include sample positioners for scanning electron microscopes, tools for minimally-invasive surgery, and dexterous linkages for microrobots. One of the envisioned devices is the micro-scale equivalent of the three degree-of-freedom (DOF) spatial manipulator shown in Figure 1 [1]. This device is controlled by three fixed single-DOF rotational actuators.

Figure 1. Spatial three-DOF parallel manipulator employing rotational actuators.

In general, manipulators can be fabricated in either serial or parallel configurations. A parallel manipulator allows multiple degrees of freedom to be attained while all of the actuators remain on the base. In contrast, a multiple-DOF serial manipulator requires some form of actuation at the intermediate joints. It is not practical to mount microactuators on moving links; therefore, all control inputs to a micromanipulator must originate from the fixed base. Because translational deflection is the easiest form of microactuation, base-connected sliding, or prismatic, inputs are preferred to the base-connected rotational actuators depicted in Figure 1. Parallel mechanisms, in which several base-mounted input actuators control a multiple-DOF device, are very well suited to the constraints of microfabrication technology [2].

SCS was chosen as the 3DMEMS structural material because of its favorable mechanical and electrical properties and its suitability for direct integration with electronics and other MEMS components [3]. For example, SCS has no grain boundaries, making it a perfectly elastic material. Fatigue is generally not a concern for devices that operate at temperatures below 800 °C [4]. The electrical resistivity of silicon can be adjusted through impurity doping; additionally, silicon possesses a stable oxide that is an electrical insulator. Robust, high-aspect-ratio SCS structures can be produced by various micromachining techniques.

This thesis is organized as follows. In the remainder of Chapter 1, general microfabrication techniques and specific processes for fabricating 3-D microstructures are reviewed. The advantages and disadvantages of these processes are discussed in relation to batch fabrication of 3-D devices. In Chapter 2, the novel 3DMEMS process is introduced. Process steps are described in detail along with fabrication results, and process improvements are discussed. In Chapter 3, a simple method for microactuation is introduced that is compatible with the 3DMEMS process. A model of actuator performance is derived, and predicted behavior is compared to experimental measurements. A design strategy is also presented for optimizing actuator performance. Finally, Chapter 4 includes a summary of work accomplished and recommendations for future work.