At large current levels, there is a

considerable discrepancy between predicted values and experimental results.

This discrepancy is believed to be caused by the strong temperature

dependence of silicon properties such as the thermal conductivity and the

coefficient of thermal expansion. In the next section, a numerical solution

of the heat equation is introduced that incorporates temperature-dependent

properties of silicon.

In this study, the resistivity of silicon is

assumed to be independent of temperature. However, at high temperatures, the

resistivity also shows a strong temperature dependence, as shown in Figure

25. The change in the deflection curve at high current values is caused by

this behavior. At the intrinsic temperature point, intrinsic and dopant

charge carriers are equal and the resistivity is at a maximum [46]. The

intrinsic temperature of the SCS used in this research is estimated to be

800 K. Silicon that has been doped to a different level of electrical

resistivity will have a different intrinsic point.

Figure

25. Silicon resistivity versus current (left axis) and V-beam deflection

versus current (right axis).

When the intrinsic temperature is exceeded in

the beam, the silicon demonstrates a negative temperature coefficient of

resistivity. This effect occurs first at the middle of the beam, where the

temperature is highest. During testing, the actuators began to glow as

current was increased beyond the intrinsic point. When current was increased

further, the actuators melted. Therefore, the intrinsic temperature is

recommended as the maximum operational temperature of the V-beam actuators;

the corresponding current should be regarded as the maximum operational

current.

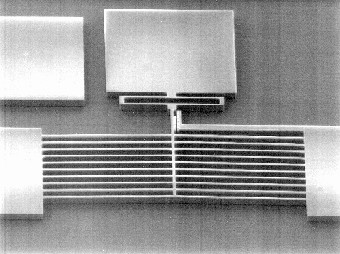

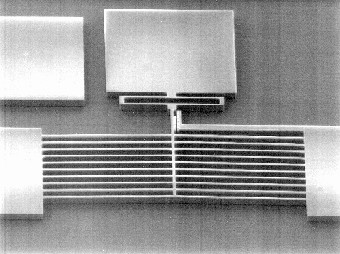

To measure force, some V-beam actuators are

connected to folded flexures, as shown in Figure 26. An array of ten

actuators is used to scale up total force for easier measurement. For any

given power, these actuators deflect less than free actuators because of the

stiffness of the folded flexures. Because of the linear relationship between

deflection and force, the following relationship can be written:

(39)

Figure

26.

Micrograph of folded flexures used to measure V-beam actuator force. Show

video (529 KB .mpeg file).

In this equation, ut is the

deflection of free actuators, uk is the deflection of the

actuators connected to folded flexures, Fk is the opposing

force from the folded flexures, Ft is the force exerted by

a single actuator at zero deflection, and k is the flexure spring

constant. This equation can be rearranged to give

(40)

The flexure spring constant is calculated from

the geometry of the flexures and is approximately 200 N/m for the

configuration used in this study. In Figure 27, actuator force versus

applied current for two actuator configurations is shown. Again, widths are

given as fabricated, and solid lines represent predicted results. There is

good agreement between the measured values and predicted values, which are

calculated by using the thermomechanical analysis described above. In

practice, uk and ut are measured by

recording uk versus current while the folded flexures are

attached, then breaking the flexures off with a probe tip to allow

measurement of ut versus current. Errors due to variations

during fabrication are eliminated by using the same thermal actuators for

both measurements.

Figure

27. Force measurements versus current for two V-beam actuators. Solid lines

represent predicted results.

Transient experiments were performed on the

V-beam actuators with a laser Doppler vibrometer. These tests were performed

by mounting a chip vertically and focusing the laser on the side of an

actuator beam. The normalized frequency response of a V-beam actuator with a

length of 1000 mm and a fabricated width w'

of 8.4 mm is shown in Figure 28. As expected, the

full range of motion is maintained at low frequencies. As the frequency

increases past 100 Hz, response drops 20 dB per decade because the actuator

cannot complete each heating/cooling cycle fast enough to keep up with the

signal. By fitting a curve to the frequency response, the time constant of

this actuator is estimated at 1.6 ms, as shown as the solid line in Figure

28.

Figure

28. Normalized amplitude versus frequency for V-beam actuator. Solid line

represents fitted time constant.

The first-mode time constant t1

can be predicted by using Equation (36) and the material properties listed in Table

3 and Table 4 [37]. Because the properties of silicon

vary with temperature, values are calculated at 298 K and 800 K, the

recommended operating temperature range of the actuators. The time constants

are predicted to be 0.8 ms and 2.0 ms, respectively. These values fall on

either side of the measured time constant. It should be noted that the

voltage during transient testing was not high enough for the actuator to

reach 800 K; however, this temperature is used because it represents the

maximum actuator temperature at the maximum operational current.

Table

4. Selected parameters for transient analysis.

|

Temperature

|

Thermal

conductivity (ks) |

Specific heat (c)

|

Predicted

first-mode

time constant (t1) |

|

298

K (room temp.) |

148

W/m-K |

700

J/kg-K |

0.8

ms |

|

800

K (intrinsic point) |

42

W/m-K |

885

J/kg-K |

2.0

ms |

Measurements were also performed to determine

whether actuator performance is affected by repeated use. A 1200 mm

long actuator was operated for over 60 million cycles with a 10 V square

wave input at 50 Hz. The deflection was observed to be 14 mm with a variation of less than 1 mm

during the course of testing. During this research, no V-beam actuator was

observed to fail while being driven at less than the maximum operational

current.